How Products Are Made, Part One: Initiation

Ended soon

We audio people often discuss products of all sorts, whether audio components, music media, accessories and so on, but do we really know much about how these are made and what goes into their creation? I have had the pleasure and done the hard work of being involved with directing the manufacturing and marketing of many thousands of products over my career and thought it would interest Copper readers to get some insight into the process.

Much of my career has been on the company or corporate side. I have not always been the artist, inventor or tinkerer that conceives and builds a product but I have worked with and for these people and the process is still much the same. Whether a corporate or individual effort, the motivations are also generally much the same (despite some views to the contrary), but the various approaches taken by different people can explain the differences in outcomes of sales (in numbers of products sold) and also the price of the product. Don’t you ever wonder why there is such a wide spectrum of prices for similar items such as loudspeakers or amplifiers, for example?

I will be doing a series of articles, as the process of bringing a product to life is both complex and long, and perhaps you do not want to read a short novel here. I will focus specifically on audio products, though I have been involved in the making of many other types of items and the process is much the same. My hope is to give you some insight and maybe even delight regarding the hard work that goes into most every item offered to the public.

It all starts with inspiration. This could be of the corporate type, the search for more sales and profits. It could also come from the basic idea of better serving and helping people through a new or better product. It might be a brainstorm of an inventor, mad scientist or researcher. Or inspiration may be result of other factors, such as the availability of new semiconductors, software, loudspeaker driver materials or production techniques. For example, look at Gayle Sanders’ Eikon loudspeakers, which are about as different from his earlier work on Martin-Logan electrostatic speakers as possible and which couldn’t have been produced until recently.

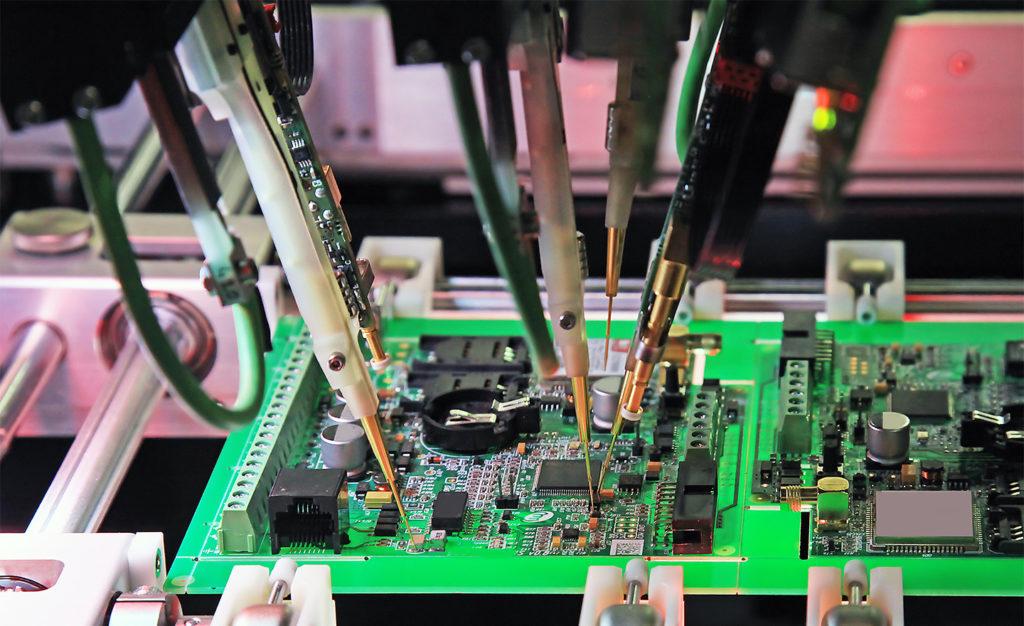

Courtesy of Wikimedia Commons/TechnoDesigner.

Courtesy of Wikimedia Commons/TechnoDesigner.

It is often passion that drives things, but it can equally be a dispassionate consideration of the market and the needs of customers. In my career what I have seen as the common elements: the product solved someone’s problem, or delighted them more, or offered some new function, experience or ability. None of this is particular to any product type, price point or market, though of course those factors may affect the number of products sold.

Even inspiration needs to be enabled by practical reality. This is where preparation, research and defining what you may be attempting to build come into play. As you may imagine, this process again varies widely. In large audio companies like Sony or Harman, for example, very broad areas of research can be involved as these firms make almost every variation of audio product, while smaller or more focused companies may limit their efforts to amplifiers, loudspeakers, digital processors, etc. Successful companies may often expand their areas of interest to related items both horizontally, i.e., branching out from manufacturing loudspeakers for stereo listening into home theater audio, multiroom audio solutions and headphones. They can also expand vertically, such as Sony going from their audio roots into making televisions, cameras and other electronics.

Generally, this revolves around the engineering skills and capabilities a company has or is interested in. Consider that Dyson has gone from making vacuum cleaners to heaters and cooling products, hair dryers and even electric vehicles – all related to their expertise in compact digitally-driven motors.

In contrast is the work of the restless minds of inventors and mad scientists (we might have a few of those in the audio world!). I am not sure how to describe someone like Bob Carver, but we have seen him make innovations in amplifier technology several times in his career, including his recent cool-running tube amplifiers, as well as signal processing (like his Sonic Holography patent), loudspeakers and more. Although his inventions can arise from his “skunk works” type of outside-the-bureaucracy approach, it still at its core revolves around a lot of research into what is feasible and the building of many prototypes and proofs of concept to see if an idea can be made real.

Courtesy of Wikimedia Commons/Hannes Grobe.

Courtesy of Wikimedia Commons/Hannes Grobe.

Another approach can be seen in the work of Dr. Floyd Toole, who (along with now many other loudspeaker designers) used rigorous scientific methods to measure and understand people’s listening preferences. Through his research, Toole developed a frequency response preference curve that today informs the work of many other loudspeaker designers (though other designers do not follow this curve at all). Yet another method can be seen in the early work of Mark Levinson, whose motivation and inspiration were to build the best audio equipment possible at the time, and he hired excellent engineers and cut them loose with no budget restrictions in mind.

Inspirations then, comes from many areas, and let us not discount the more basic motivations of seeking more profits and sales; keeping up with technical developments, or of simply responding to what the competition is doing or to market needs. Wireless audio, streaming audio and powered speakers come to mind as example of products driven by the aforementioned factors. Industrial design is another factor – today, mainstream consumers want smaller, sleeker and more portable products, and better fit and finish.

To be clear, though: inspiration is where new product development starts, but that, along with motivation and research and development in and of themselves do not make a product. Instead, they make the basis for a product possible – and drive its creation.

What comes next is a target. Some firms call this a PID or Product Initiation Document, while others may not be so formal. It can be a statement of who the product is being made for, some of the goals of the product, how big the market opportunity is, facts about its competitive positioning, the likely selling price, the methods of selling and marketing the product, and other details needed to consider if the project has a chance of being successful.

Even something like a small vintage transistor radio involves a lot of design and engineering work.

If you cannot define these things, then let’s say you are probably making art, which of course is done for its own sake and not for commercial reasons. Certainly, some audio components and many other technical creations are art according to this point of view. and may turn out to be expensive, rare, odd or different and often only for the few.

As we will see going forward, these considerations and others regarding methods, technical solutions, materials, fit and finish requirements and other choices affect the quantity and the cost of the products and have significant impact on the product that is ultimately sold to the consumer. It is not easy or simple to make a product. It can and often is a difficult path if not a marathon.

The target also doesn’t define the product itself; it’s just a goal to try to achieve. To get there we must go back through our research, we must look into the parts and components needed for the product and see if we can in fact come up with a design and a bill of materials that can fit the requirements.

Indeed, we now have to closely define these requirements in what is generally known as a PRD or Product Requirements Document. As we go over the parts lists and argue costs, we also need to precisely define the features and functions of the product. Each feature, each button, each part often needs to be reviewed to see if it is needed, because each one adds to the complexity of the product and of course its cost.

One of the paradoxes of product development then becomes clear: it is harder to make a good inexpensive product than a cost-no-object one. Industry people say this not to make light of expensive, rare or luxurious products but only to point out that making inexpensive products often involves tougher choices. If you can just keep raising the price that is easier than having to choose between which part, level of finish, level of performance to make your product. No disrespect meant for high priced product but it is a fact. In other sections of my series on the other hand I will point out the tough spot small makers are in that often make it hard and expensive to make products.

In the end, the market decides what is worthwhile or good. I have seen gold-plated feet ruin the profitability of certain audio components and cause their failure – and as it turned out, it was a feature that most buyers did not even notice or care about. I have also seen the opposite, where a lack of care in these same sorts of details caused a product to fail. Also, many potential products don’t even get to the see the light of day. As the process of product definition works its way through development, many products are “killed” when they show they cannot “close the gap” enough to come close to the goal, while others may evolve in unforeseen ways – becoming more or less feature-rich, more or less expensive, or evolve in terms of their feature set, their place in the competitive market or their customer target.